Believe that obsolescence will never affect you? Think again.

Written by: Tahel Kedem

As technology changes, it can be tempting to long for the old days when electronics were simpler. Now, as technology develops faster than ever before, we are seeing that customers are experiencing obsolescence more and more. While the defense, security, and medical industries have always experienced significant obsolescence, my colleagues and I are now seeing that no one is immune, making it more vital than ever to have a plan in place to protect against obsolescence.

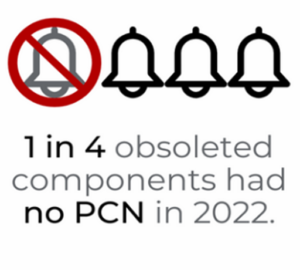

In fact, we recently saw many of our customers impacted by the acquisition of a large semiconductor manufacturer. The acquired company’s parts were less profitable, and many went obsolete with little to no notice. Several customers were unprepared for this and missed the last-time-buy deadline. Now they must work towards a redesign. Last year alone, 1 in 4 of all obsoleted products went obsolete with no product change notice (PCN), leaving companies scrambling.

Despite the rising prevalence of obsolescence, there are things that companies can do to protect their supply chains.

Monitor Supply Chain Patterns

The first step is always to remain aware of supply chain patterns. Planned obsolescence has been an issue for a long time, particularly prominent in consumer electronics, and remains a dilemma across the entire electronics industry. For example, smart phone manufacturers were recently under fire in South Korea for deliberately slowing the performance of older devices (Source: Forbes).

Monitoring supply chain patterns and planned obsolescence patterns will help you build resilience into your supply chain and give you foresight into last-time-buys you may need to be on the lookout for.

Invest in the Sustainability of Your Supply Chain

Additionally, it is vital to invest in the sustainability of your supply chain. This simply means that you should know your supply chain from end to end, not just your core components. Partnering with distributors early on will ensure that you always have a backup plan should one of your components go obsolete with no PCN. Working with Converge provides you with access to assistance locating hard-to-find components, a partner that optimizes value recovery with your excess inventory, and insights and visibility not available anywhere else.

The bottom line is this: no one is immune to the dangers of rising obsolescence, so if you believe that obsolescence will never affect you, THINK AGAIN.

Join us this year at our in-person Future of Obsolescence Management conference, this September in Boston, Massachusetts for a thought-leadership community that is working to write the Future of Obsolescence Management together. Learn more and register today.

About the Author

With more than 28 years of experience in the electronics industry, Tahel Kedem is a skilled Country Manager here at Converge. Her expertise in obsolescence and experience throughout the whole electronics supply chain make her insight invaluable to her customers and colleagues.